Jaguar Land Rover’s 3D-printed glove helps workers on production line

By Staff Writer 25 September 2019 | Categories: news

With 3D printing available for a while already, practical solutions perhaps haven’t been enough to quite live up to the initial hype. Luckily, we’re seeing more and more innovative usage, case in point a new glove coming from Jaguar Land Rover (JLR).

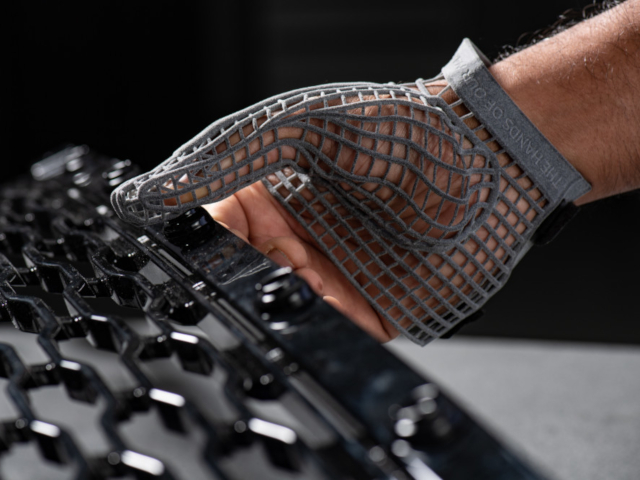

Engineers from the company are working on the next generation of protective workplace clothing - a lightweight 3D-printed glove. JLR believes this could help better protect employees from the threat of a musculoskeletal disorder.

JLR notes the 3D glove is designed for people working on the production line, for example those required to fit clips or fasteners into the chassis during assembly of Jaguar and Land Rover’s luxury vehicles.

Musculoskeletal disorders, which include more than 100 different types of conditions, make up around 30% of all workplace injuries that result in time off, and account for a third of the money paid in compensation to employees. Musculoskeletal disorders affect an estimated 10% of the global population, rising to as much as 40% in certain industries.

Engineers at JLR’s Gaydon site – home to one of the largest 3D printing facilities in the UK – saw an opportunity to use the company’s advanced manufacturing expertise to design and 3D print a lattice-style structure. This would provide support to reduce muscle fatigue, but also be flexible and comfortable enough to wear during an eight-hour shift. Using 3D computer-aided design (CAD) software, the team modelled designs in different densities using a variety of materials for testing.

Following feedback from trials, the team is now working on a second-generation prototype. It will include a foam pad made using impact additive D30 - a polymer material which absorbs impacts when placed under pressure. This will make the glove suitable for those who fit parts, such as door casings, using the palm of the hand.

In the short term, JLR states the gloves will support workers across its facilities, helping to protect against musculoskeletal disorders. These form part of a wider future plan to deploy a range of technologies to assist those with muscle weakness or patients who suffer from physical or neurological disorders, helping employees return to work.

The JLR Additive Manufacturing Centre produces over 80,000 parts a year for a variety of applications, including functional prototyping, design mock-ups and manufacturing assembly aids and fixtures. JLR is also able to 3D print parts for production cars with the Jaguar XE SV Project 8 one of the first vehicles to use them.

The programme forms part of JLR’s Destination Zero vision, an ambition to make societies safer and healthier, and the environment cleaner. Delivered through relentless innovation, the company’s focus is on achieving a future of zero emissions, zero accidents and zero congestion, across its facilities, and through its products and services.

Most Read Articles

Have Your Say

What new tech or developments are you most anticipating this year?