Additive manufacturing or 3D printing of industrially-relevant high-performance parts and products is today a reality, especially for metal additive manufacturing technologies, and is used globally for the production of end-use, mission-critical parts.

But while the design complexity now made possible by additive manufacturing makes it particularly useful to improve product performance in various applications, the structural integrity and long-term (cyclic-loading) performance of such complex structures is sometimes still in question.

In a comprehensive review article published in the high-impact journal Materials Science and Engineering R recently, a group of international researchers argue that our knowledge-base has increased to such an extent to overcome some of the major challenges hindering the large-scale commercial production of industrially-relevant and high performance parts and products incorporating such structures.

Prof Anton du Plessis, leader of the 3D innovation research group at Stellenbosch University and one of the authors of the review article, says one of the major challenges is fatigue performance: “Fully understanding fatigue performance makes it possible to mitigate potential problems, which opens up the possibilities for using this technology in many more applications”.

Du Plessis, an associate professor in the Department of Physics at SU, collaborated with researchers from Norway, Italy and the United States for this review on the mechanical properties and fatigue performance of metallic cellular structures manufactured by additive manufacturing. These structures have many advantages but their mechanical performance needs to be fine-tuned and optimised. The review highlights specific insights in this regard for the manufacturing of fatigue-tolerant cellular structures.

Du Plessis explains: “Fatigue is the most important failure mechanism in most structures. This is caused by continued loading and unloading, creating cracks over time, so it is important to prevent it particularly for high-performance parts like those used in aeroplanes, cars and medical implants. Fatigue failure is often driven by defects, microstructural imperfections, residual stresses, surface roughness, and, as this review has also highlighted, strut junctions in lattice structures.”

Overcoming the challenge of fatigue failure

The review shows that the effective use of these light, high-performing structures depends on an understanding of the design parameters, materials and manufacturing parameters, in order to achieve good mechanical properties, Du Plessis explains.

“Technological challenges have affected the quality of their production so far, leading to some doubts over their widespread use in the past. This includes defects in parts, lack of fusion, poor surface finish, residual stress and distortion. But it has been proven that excellent properties can be achieved by considering all the above factors, and that some cellular architectures are better suited to achieve high-fatigue performance.

“We believe the growing knowledge base in this area will allow a better understanding of these meta-materials and specifically on how to achieve best performance from them, for various new applications. It is clear that many new applications of these structures are waiting to be revealed in different industries and application areas,” Du Plessis concludes.

What is additive manufacturing?

Additive manufacturing (AM), also known as 3D printing, is the general term used for processes that join materials to make objects directly from 3D model data, sometimes by using thermal energy or lasers to add layer upon layer of materials. Metal AM is extensively used in many industries, such as the automotive, aerospace, sports and biomedical industries, where reliable, fatigue tolerant, strong, yet lightweight, materials are an important requirement.

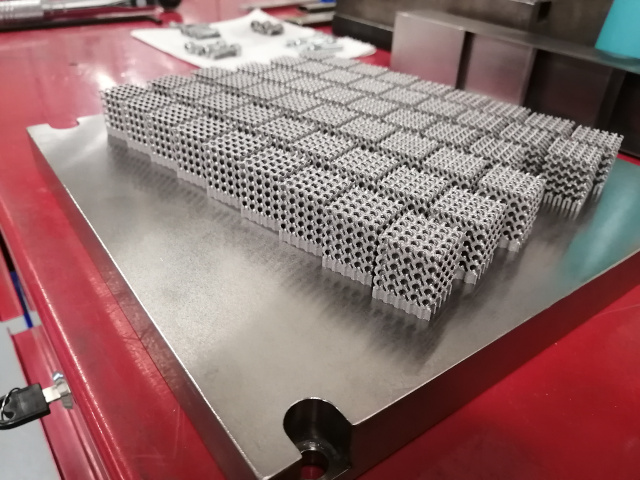

Porous cellular or lattice structures are a complex design style made possible by AM. These can be tailored or architected for unique mechanical or other performance requirements and have many advantages including large surface area, low mass, a regular repeated structure and open, interconnected spaces. Using AM makes it possible to more precisely control the micro-architecture of these structures to optimise their shape, weight, stiffness and strength.

These structures are particularly useful for long-lasting medical implants (ranging from ’standard’ knee and hip implants, to customised patient-specific bone implants) and for lightweight automotive and aerospace components. These are the main industry drivers currently.

Cellular structures are particularly well suited to creating complex individualised designs for medical implants because they are lightweight, long-lasting and allow bone in-growth into the porous metallic structure, allowing a stronger attachment and higher success rate. Many new applications are waiting to be discovered for these architectured cellular structures, with some interesting developments and potential in fluid flow and thermal management applications in high-performance engineering devices.